Multiple Sample Etching in PlasmaEtch

Did you know that multiple samples can be processed at the same time in the Nisene PlasmaEtch? Because we have a 20x20mm effective decap zone, if multiple samples can fit in the 20x20mm one, they can all be decapped at the same time.

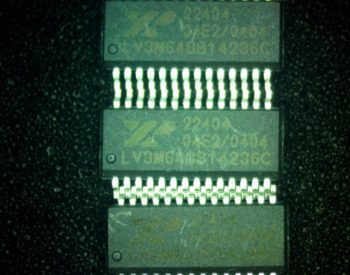

Take for example the sample in Figure 1. This EXAR sample is approximately 4mm x 10mm in outer dimensions. According to these dimensions, up to 8 samples could be processed in one attempt.

Figure 1: Unprocessed sample

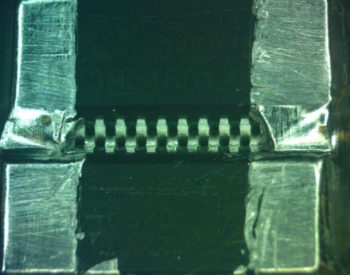

For this display, 2 samples were processed side by as shown in Figure 2. Planarity among both samples can be seen as the decap progresses from start, to wire exposure, and final die exposure.

Figure 2: Masking prep of 2 duplicate samples

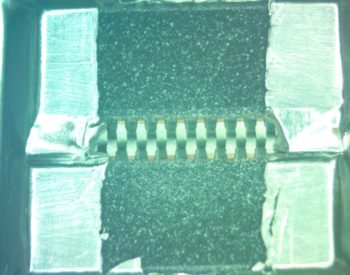

Disparities can be seen in the different steps of sample processing however; these disparities minimize as the decap continues. Figure 3 shows the early exposure of bond wires on each sample and how there is a small variation in each samples bond wire exposure.

Figure 3: Initial bond wire exposure

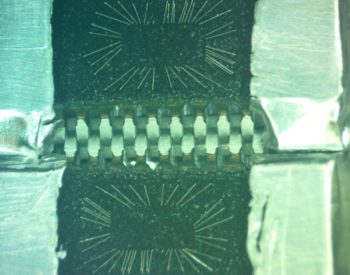

Continued processing of these samples will balance the exposure of each sample to where they closely mirror each other. In Figure 4, you will see that two short cycles of additional processing results in samples that are almost identical in exposure.

Figure 4: Near identical planarity between samples

Eventually, if needed, the end user can simply remove the completed sample(s) and continue the minimal processing needed on the remaining sample(s). In Figure 5, it can be seen that one sample is completed while the second sample still has a small amount of surface molding remaining. At this point, the completed sample was pulled and a short 10-minute cycle was run to clear the remaining molding on Sample 2.

Figure 5: Final die exposure

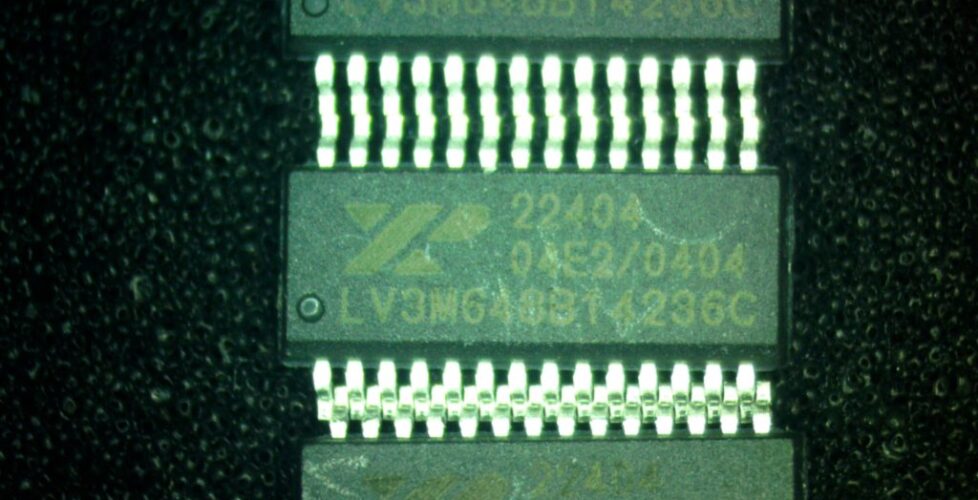

Also important to note is that this sample contains copper bond wires. While copper bond wires have been widely discussed in the FA industry for a number of years now, they still maintain challenges in the decap world. Because of large variations in the copper bonding from sample type and manufacturer, wet-chemical decap can still be hard to maintain intact and minimally compromised bond wires. That said, the Nisene PlasmaEtch can routinely maintain full wire integrity from bond to stitch, as shown in Figure 6.

Figure 6: Clean copper bond wire